Stick repair technology

The hockey stick repair technology used by "Hockey Stick Service" was developed in 2019 in cooperation with Riga Technical University. With certified equipment, samples of hockey sticks were tested for dynamic and static loads. Over time, technology has been constantly improved in order to be able to offer our customers the best repair quality with a guarantee. During the restoration of the sticks, the same materials are used as in their production process, which ensures minimal weight gain and high mechanical strength. The weight of the club after repair increases by 8-20g, the flexibility of the repair place in the shaft (flex) - up to 5%. To better understand the quality and results of our repairs, we have prepared a picture gallery below of an example of a blade and shaft repair.

BAUER Vapor Flylight before repair:

BAUER Vapor Flylight after repair:

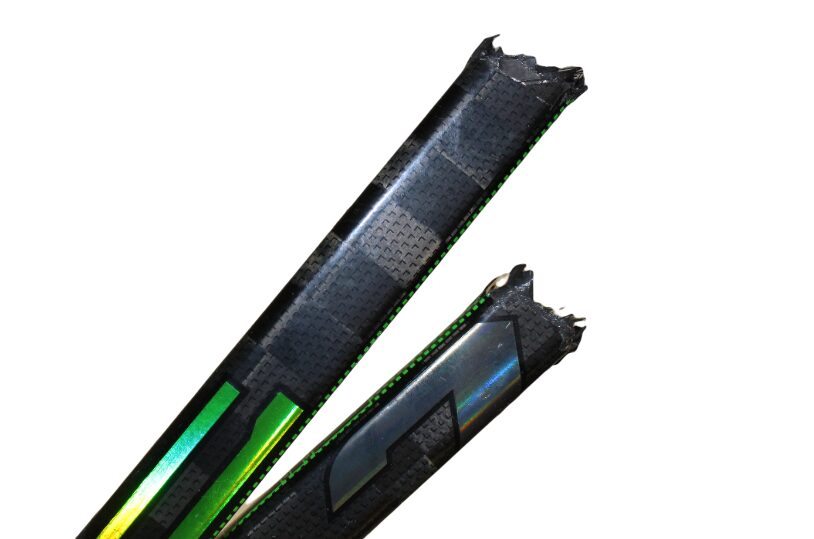

CCM Ribcor Trigger 5 pro before repair:

CCM Ribcor Trigger 5 pro after repair:

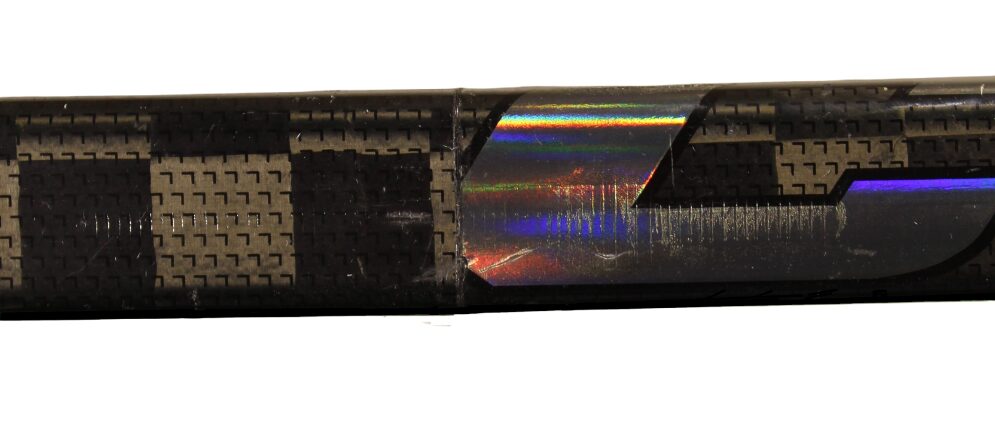

Cross section of BAUER Nexus Geo shaft after repair: